capsule filling machine working principle

It has 9 holes turning out a highest output of 1200 capsulesminute. Stable operation safe and reliable.

Tamping Pin Type Capsule Filling Machine Working Principle

Thats despite being used extensively in the process to produce medical drugs and supplements forms.

. Most capsule filling machines or encapsulators have a 200-300 bed hole a loading tray a powder tray and a pin plate. A capsule filling machine is one of least known and understood machines in the manufacturing world. This machine makes various sizes of capsules.

Pharmaceutical processing involves several operations and capsule filling is one such important part of the process. Let us discuss some of the most significant parts. It shows how many capsules the machine can fill per time and affect the maximum filling speed.

Working principle of automatic capsule filling machine. NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole. Capsule Filling Machine Definition.

51 The Working Principle of Softgel Encapsulation Machines. 6 holes for 9 holes for 1200C 18 holes for 2000C and 24 holes for 3500C. In a certain proportion after 7080 C low temperature cycle mixing and melting after a period of time the gelatin is vacuumed.

Parts and Working Principle. Working principle of soft capsule filling machine and operation method Oct 07 2019. The production process fully complies with GMP regulations.

When the packaging machine is working it should ensure the ventilation of its space reduce alkaline and acid gases and keep the working environment safe. This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight when the amount of pressure of the liquid reservoir is equal to the. What is the capsule filler.

They also have a sealing rubber-cap-plate a lever and a cam handle. This can be done either manually or using a capsule filling machine. The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process.

The liquid filling machine works when the pressure is high. This machine can produce a maximum of 135000 caphr. By creating the FEC40 Fette Compacting has proven its innovative capabilities regard to the industrial capsule filling.

Types of packaging machines pdf. And develops advanced filling machines by itself. This post demystifies everything about a capsule filling machine and how it works.

Soft capsule filling machine through pre-treatment integrated ingredients adding pure water solid particle medical bone gelatin additives vitamins glycerin etc. For pellet filling the maximum capacity is 95000. Filling is possible through exchanging of parts.

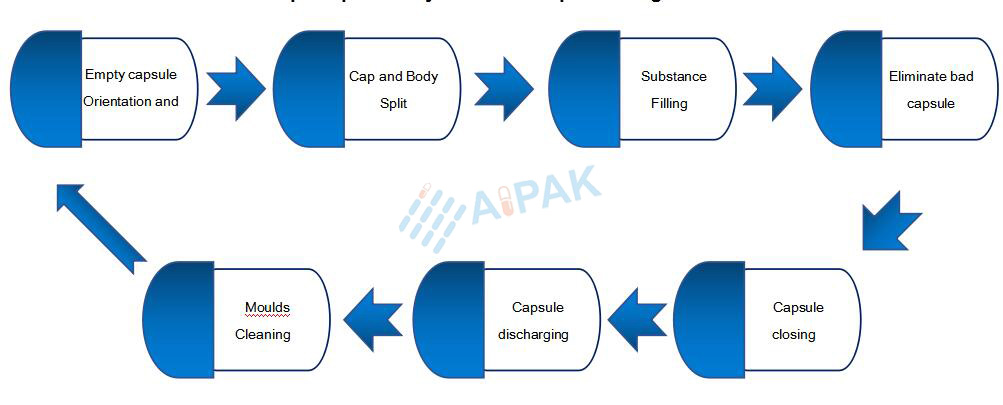

The capsules produced in a factory mostly have their caps and bodies joined and they need to be rectified before the filling process begins. Most automatic capsule filling machines can fill capsule of different sizes by changing mold. Personal capsule filling machines is for small scale production and utilization.

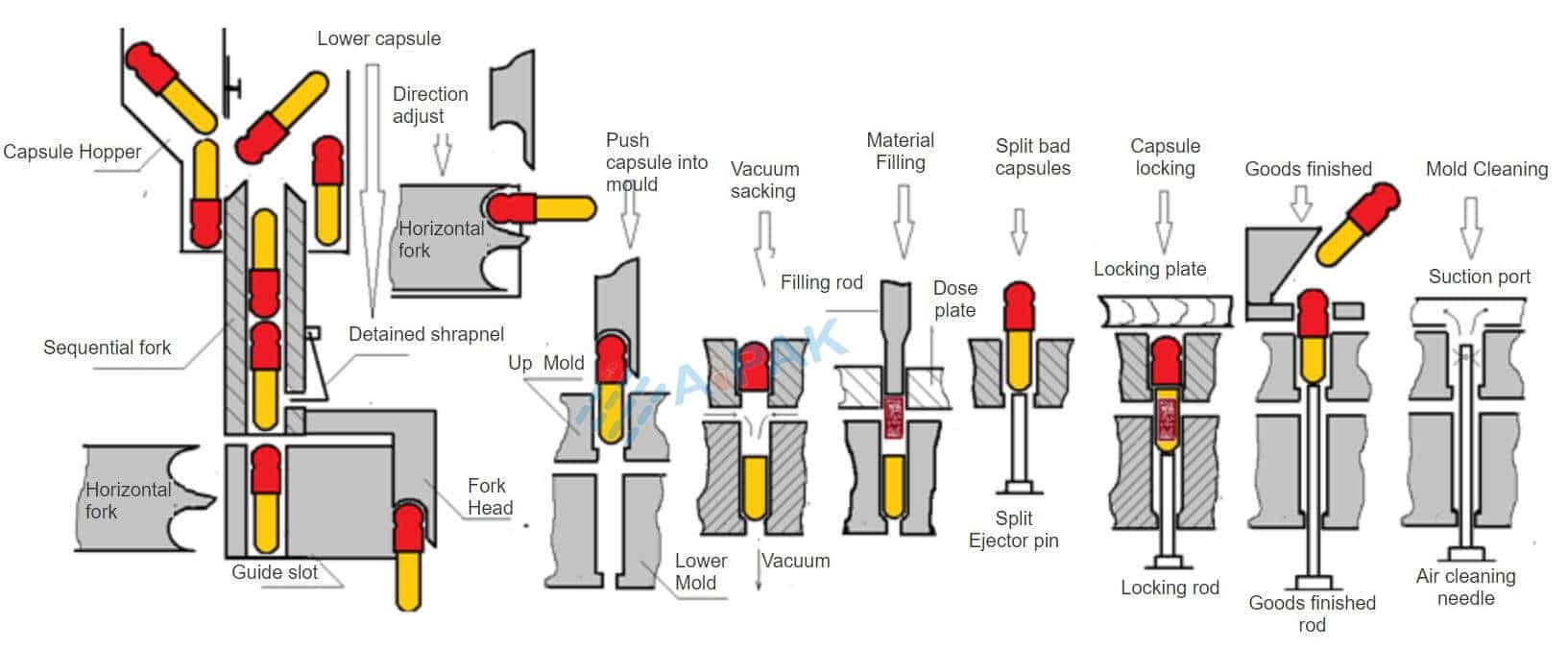

Liquid Filling Machine Its Principles. Working Principles of Various Filling Machines. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding.

The SF-135N capsule filling machine is used for various industries like chemical pharmaceutical animal food and food. Working Principle of A. Automatic capsule filling machine is a very important machine in pharmacy industry.

You can then process the Softgel capsules. On the other hand professional capsule fillers are used in pharmaceutical industries at large scale production with high efficiency. But how does a process like this wor.

Vacuum packaging machine working principle. During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous rotation The filling volume of the capsule is mainly determined by the volume of the measuring disc hole. Since its introduction to the market it has been favored by pharmaceutical research institutes.

How packing machine works. Packaging machine working principle. These personal capsule filler machines allow people to fill their capsules with the necessary medication.

Take our NJP series automatic capsule filling machine as an example. In the capsule hop per the hollow capsule the main board moves up and.

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Filling Machines Their Working Principles

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

Powder Filling Drug Absorption Pharmacological Sciences

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Capsule Filling Machine The Blueprint Guide Saintyco

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine Working Principle Ipharmachine

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Automatic Capsule Filling Machine High Speed Capsule Filler

Hard Shell Capsule Filling Machines Basicmedical Key

Automatic Capsule Filling Machine Capsule Filling Equipment China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

13 Most Important Parts Of Automatic Capsule Filling Machine You Must Know Saintytec

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Capsule Filling Machine Your Best Online Resource About Capsule Fillers